Fully Customizable Integrated System

Suitable for Over 50 Different Industries

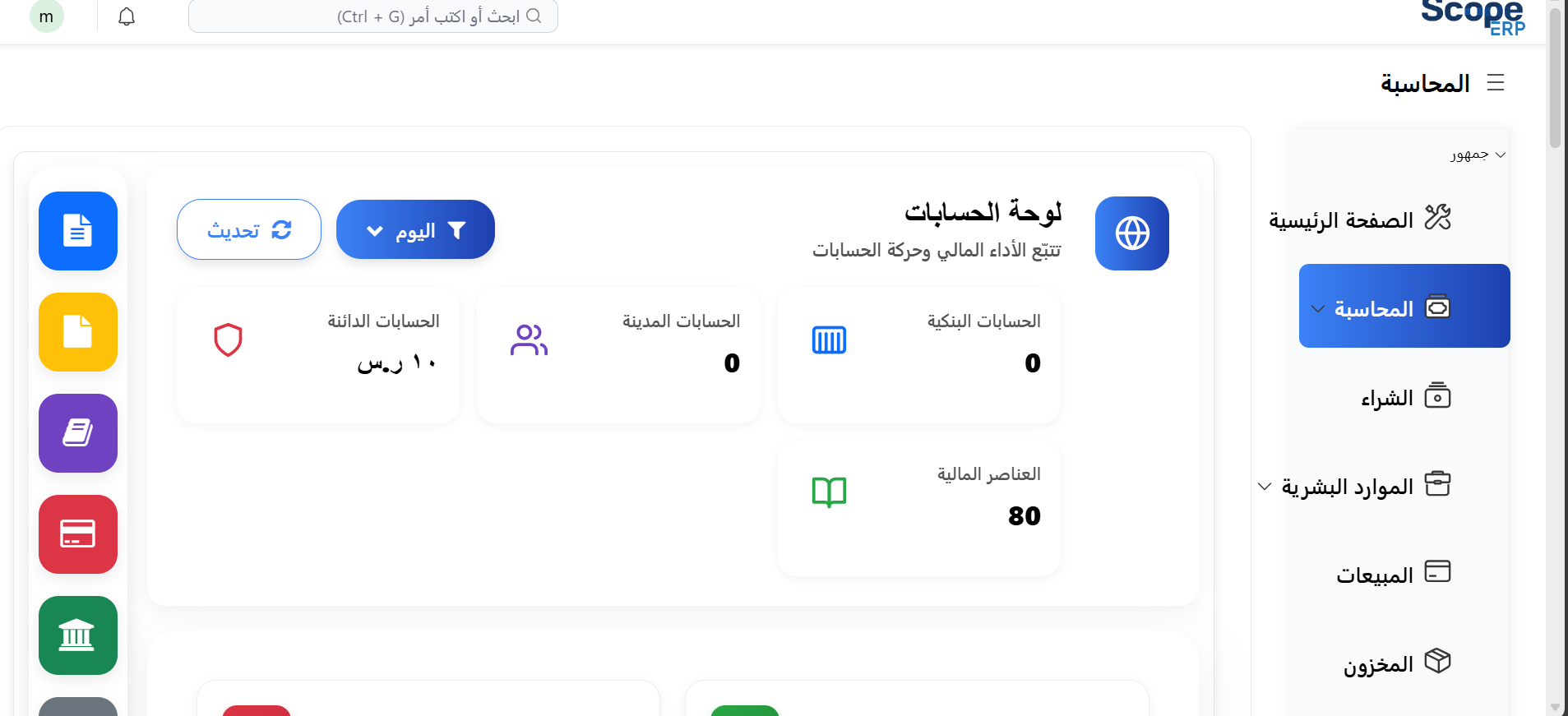

Precisely tailor the system to your business needs including various applications and designs to help you achieve your goals.

Manufacturing is the process of transforming raw materials into finished products with high efficiency and quality.

Manufacturing Module

The Manufacturing Module is one of the most critical components within modern enterprise systems. It is designed to support industrial organizations in managing the full production lifecycle — from material planning, through work order execution, all the way to delivering the final product with high quality.

The module provides an integrated view of all production activities, helping management optimize resources, control operating capacity, reduce waste, and accurately calculate the actual cost of each product. It seamlessly connects production lines with inventory, quality, maintenance, and procurement, ensuring a smooth and uninterrupted operational workflow.

The system enables the creation of multi-level Bills of Materials (BOM), management of work orders, and tracking of every stage of production from start to finish. It also allows monitoring of workstations, scheduling operational loads, and generating real-time reports on performance, completion rates, and production line efficiency — providing decision-makers with accurate and updated data.

In addition, the module integrates fully with the Quality Management System to perform inspections, record testing results, and handle non-conformities. Its deep integration with warehouses ensures automatic updates for raw materials and finished goods quantities, reducing errors and improving accuracy.

In short, the Manufacturing Module aims to manage production processes professionally, improve resource efficiency, ensure product quality, and provide clear visibility that enables industrial companies to scale, reduce costs, and accelerate production.